Freshmen Build and Fly R/C Airships

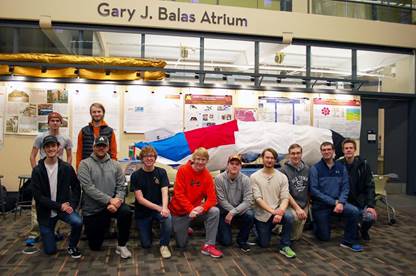

On Tuesday, December 11, students from Professor James Flaten’s freshman seminar, AEM 1301: Design, Build, and Fly - R/C Airships, put on an exhibit in the Balas Atrium in Akerman Hall. The students showed gondolas, rigid airframes, and flight videos from lighter-than-air vehicles they built over the fall semester.

Generally speaking, airships move slowly and are easy to fly. Lifted by balloons filled with a lighter-than-air gas - this class used helium exclusively - airships are able to stay aloft even without propulsion. For control, motors are attached to the bottom of the aircraft and allow them to move forward, backward (sometimes), and change both altitude and heading. In this class students first built (non-rigid) “blimps” then focused on “rigid airships,” where an internal rigid frame holds up the outer shape of the vehicle. Rigid airships are typically larger than blimps, since their displaced volume needs to lift the weight of the airframe itself, as well as the motors and control electronics.

Class members worked on three separate rounds of building, in teams. After warming up on “Project A” which used R/C parts from toy tanks to lift a tiny gondola with very small balloons, students worked on “Project B” vehicles that used Arduino Mega microcontrollers and XBee radios to control multiple motors in a gondola suspended from larger balloons. Project B teams were called Spirit of the North, Mothership, Team Shark, FLOTUS, and Flying Tigers, and each team made a short video documenting their vehicle’s flight in the lobby of Tate Lab of Physics in early November.

Later in the semester students formed two “super-teams” to work on “Project C” to build and fly rigid airships. These two teams were named Team Heavy and Team Light and their vehicles were test-flown (then left on display) in the Balas Atrium in Akerman Hall.

Some issues encountered by students while testing their rigid airships were the fragility of materials light enough to build a liftable airframe, the failure of one main battery (delaying the test-flight of the “heavy” rigid), and gaining enough forward speed (using motors) for the control surfaces on the tail to be effective for pitch and yaw control. The “heavy” rigid, in particular, was designed to use both lifting gas and motors to get off the ground (i.e. it was not genuinely lighter than air) and it turned out to be particularly difficult to control while in the air - another learning experience.

At the end of the class Professor Flaten commented “I’ve heard of classes at other universities building and flying R/C blimps, but building more-challenging rigid airships and implementing radio control ourselves (with microcontrollers and XBee radios, rather than just using commercial R/C equipment) was a good learning experience, both for the students and for me.”

Team Heavy Airship

Team Light Airship