Four different TBP-based non-Newtonian solutions were tested in the rod climbing experiments. These solutions were produced by mixing TBP (Tributyl Phosphate) and PBMA (Polybutyl Methacrylate) or PSBMA (Polystyrene-butyl Methacrylate) with specified concentrations by weight. The properties of liquids are shown in table-1.

|

Solution |

Density |

Surface Tension |

Shear Viscosity at 1.74 shear |

Weight Concentration |

Note |

|

|

(g/cm3) |

(dyn/cm) |

(cp) |

% |

|

|

PBMA/TBP-350 |

0.971 |

27.6 |

350 |

2.56 |

Mixed |

|

PSBMA/TBP-350 |

0.974 |

27.8 |

350 |

2.60 |

Mixed |

|

PBMA/TBP-750 |

0.992 |

25.6 |

750 |

3.20 |

Mixed |

|

PSBMA/TBP-700 |

0.974 |

26.2 |

700 |

3.10 |

Mixed |

Table 1. Properties of experimental liquids

(a)

(e)

(b)

(f)

(c)

(g)

(d)

(h)

Fig. 1 Change in free surface of

PBMA/TBP-750 near a steel rod (diameter ![]() cm) as rotational

speed is increased; room temperature

cm) as rotational

speed is increased; room temperature ![]() ºC.

ºC.

(a) (b) (c) (d) (e) (f) (g) (h)

Speed (rev/s) 0.0 4.2 6.7 10.0 13.3 20.0 30.0 41.7

(a)

(e)

(b)

(f)

(c)

(g)

(d)

(h)

Fig. 2 Change in free surface of

PSBMA/TBP-700 near a steel rod (diameter ![]() cm) as rotational

speed is increased; room temperature

cm) as rotational

speed is increased; room temperature ![]() ºC.

ºC.

(a) (b) (c) (d) (e) (f) (g) (h)

Speed (rev/s) 0.0

4.2 6.7 10.0 13.3 20.0 30.0 41.7

(a)

(e)

(b)

(f)

(c)

(g)

(d) (h)

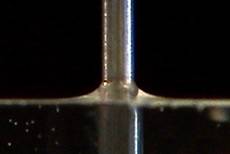

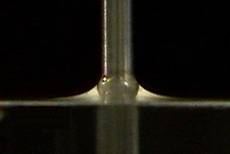

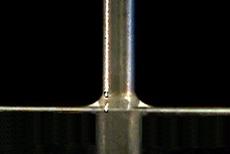

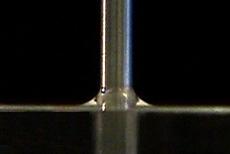

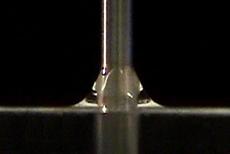

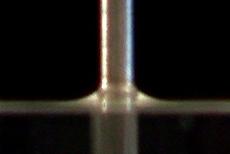

Fig. 3 Change in free surface of

PBMA/TBP-350 near a steel rod (diameter ![]() cm) as rotational speed is increased; room temperature

cm) as rotational speed is increased; room temperature ![]() ºC.

ºC.

(a) (b) (c) (d) (e) (f) (g) (h)

Speed (rev/s) 0.0 8.3 13.3 20.0 25.0 36.7 50.0 65.8

(a)

(c)

(b)

(d)

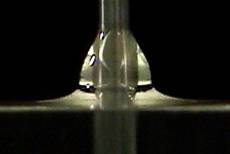

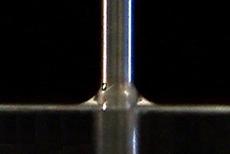

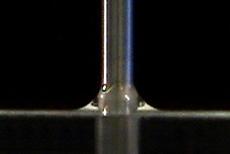

Fig. 4 Change in free surface of

PSBMA/TBP-350 near a steel rod (diameter ![]() cm) as rotational

speed is increased; room temperature

cm) as rotational

speed is increased; room temperature ![]() ºC.

ºC.

(a) (b) (c) (d)

Speed (rev/s) 0.0

8.3 16.7 65.8

A summary of the climbing constants for the TBP-based liquids is shown in table 2.

|

Solution |

h0(a) |

h2(a) for Wà0 |

Climbing constant |

|

- |

cm |

cm.sec2 |

g/cm |

|

PBMA/TBP-350 |

0.13850 |

0.00070 |

2.23 |

|

PBMA/TBP-750 |

0.11491 |

0.00234 |

7.30 |

|

PSBMA/TBP-350 |

0.11202 |

0.00042 |

1.35 |

|

PSBMA/TBP-700 |

0.16727 |

0.00189 |

5.89 |

Table 2. Measured values of climbing constants (the radius of rod a = 0.12 cm)