Isolation Table

Home

Dynamic

Magnet

The

isolation table was designed to hold various equipment including a

microscope above the magnet. When the pole cylinder is being

turned, there are huge tangential forces exerted on the dynamic magnet

base. Although this base is constructed of steel and

probably weighs a ton, these forces are sufficiently large to shake the

table! To overcome the effect of these vibrations on a

microscope, an isolation table was designed to float above the dynamic

magnet.

The table is an MDF frame with a construction foam interior for

strength. On the top is a 1/4" Al plate with 1"x1" 1/4-20 square

hole pattern for mounting hardware. The amount of metal used in

the table construction was limited to reduce stray magnetic fields and

eddy currents during dynamic operation. The screws used were

stainless steel for their nonmagnetic/nonconducting properties.

The table sits on four air isolation chambers which in turn sit on four

concrete columns. The isolation chambers provide an automatically

leveled surface with variable height. They don not, however, have

any other motion controls. This presented a problem as the travel

of the table exceeded the dimensions of the sample area and endangered

sensitive sample and probe equipment. To overcome this dilemma

four steel brackets were attached to the dynamic magnet base

table. A limit stop (long screw) was then added to the brackets

to control the motion of the floating table.

Overall image of the rotating magnet and isolation

table. In this picture you can see the cement bases on which the

isolation columns sit; the motion limiting stops on the front and right

sides; various instruments. Click Here for the SOLIDWORKS

ASSEMBLY file for the floating table.

Front-side image of isolation table.

The probe and microscope motion controls are

visible.

Triple-axis motion control and the transverse Hall

probe are used to characterize the static and dynamic fields.

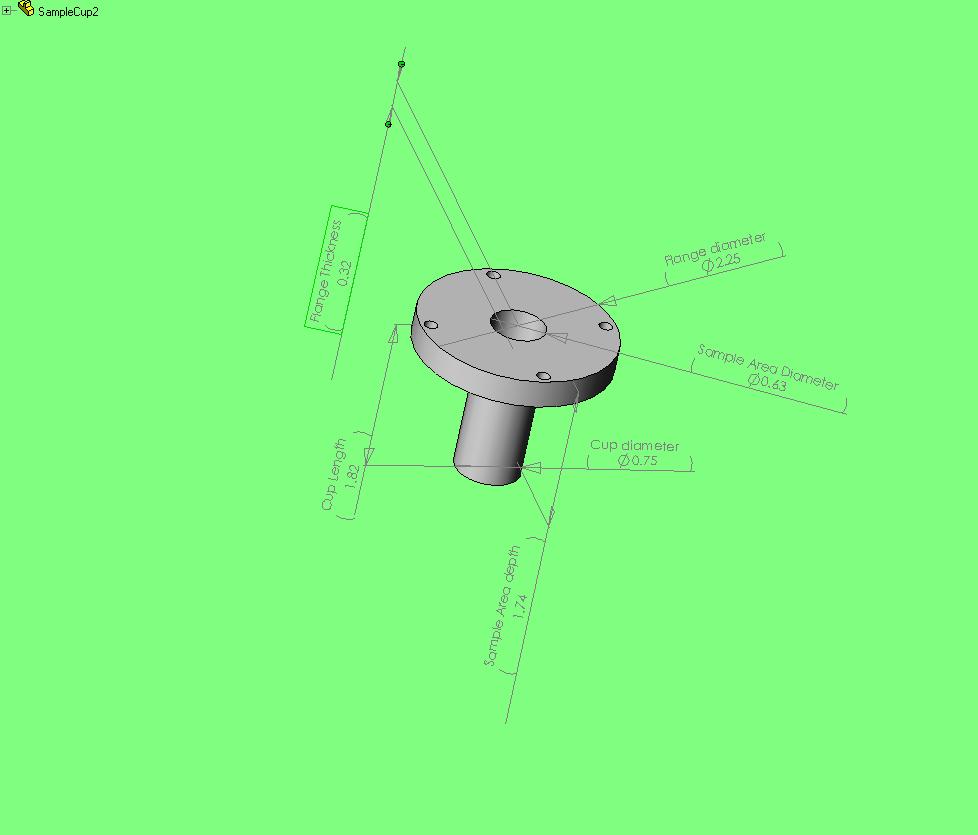

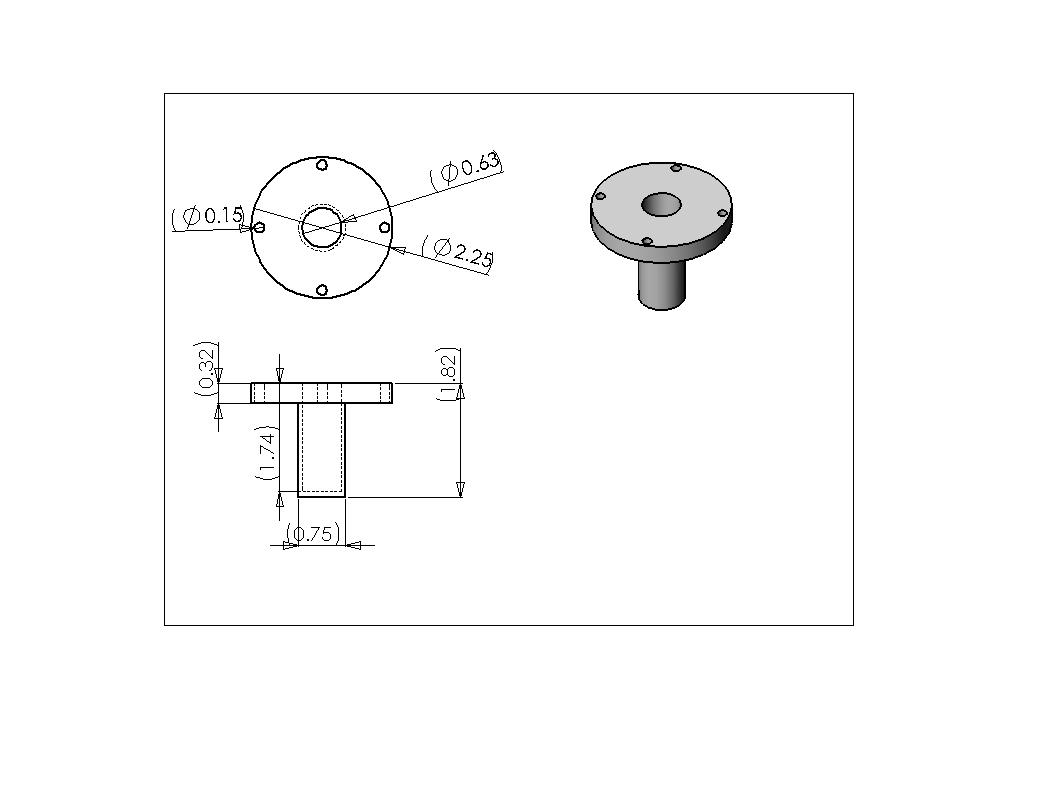

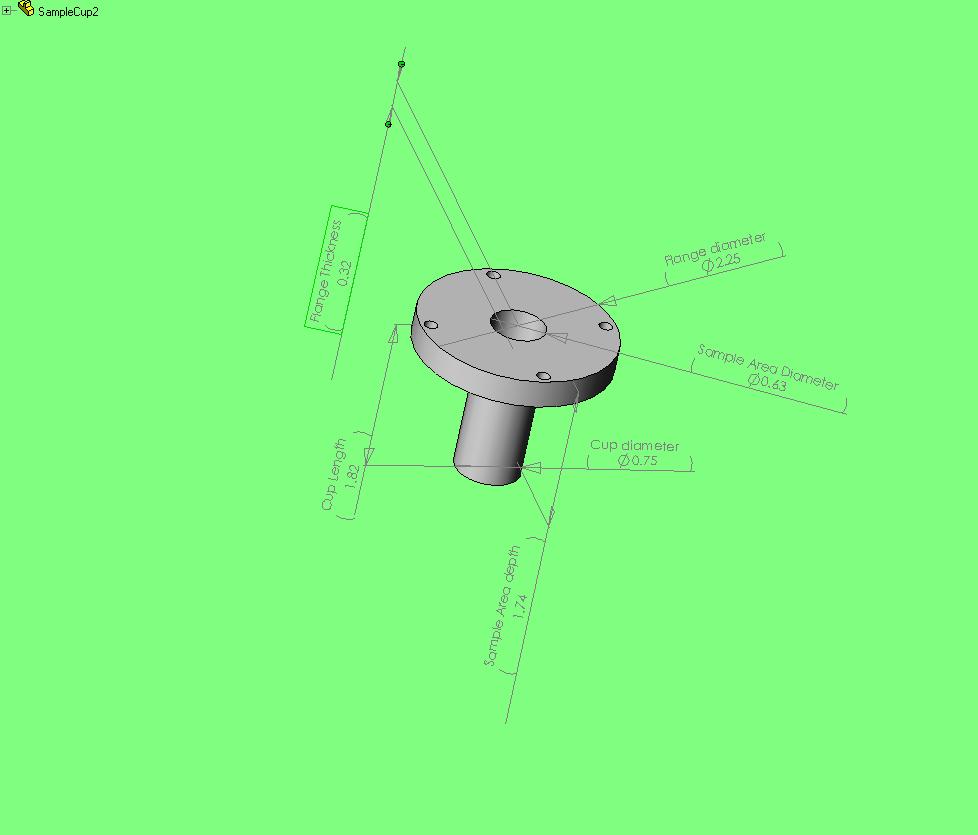

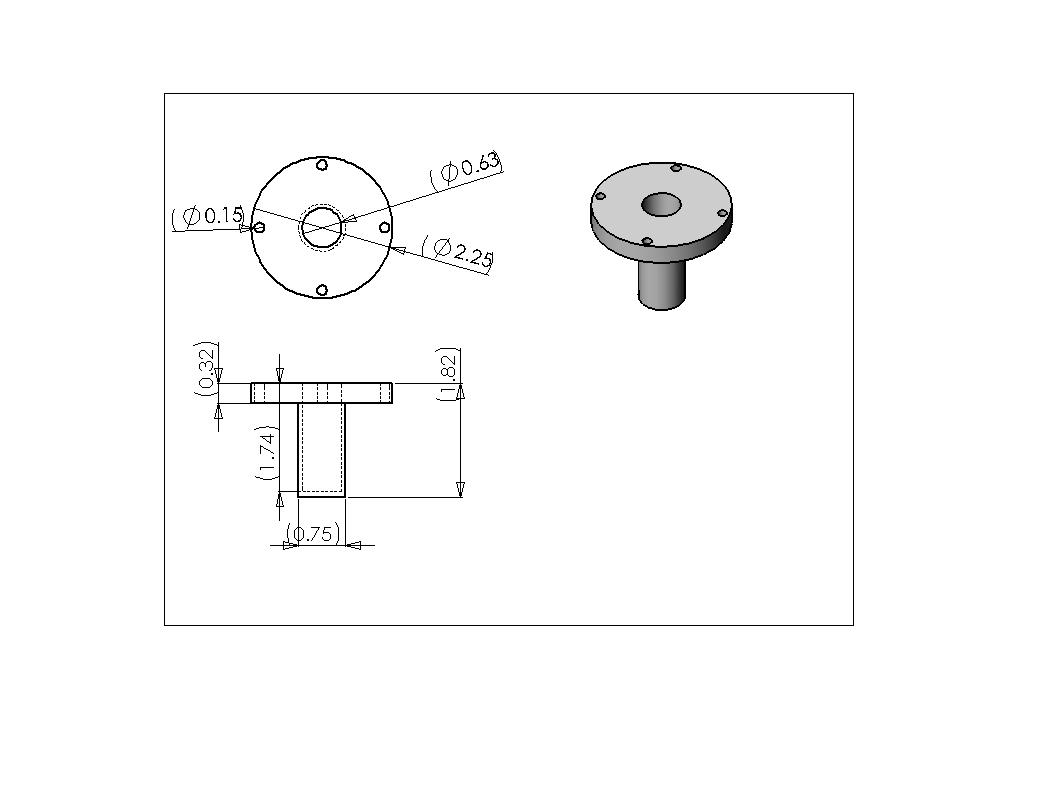

A plexiglass plate is held ~2mm above the rotating

cylinder. Its purpose is to keep stray

objects from getting stuck between the cylinder and the box. Centered in this plate is a circular cup

designed to keep probes and specimens away from the walls of the

rotating

cylinder. Click Here for the cup as a

SOLIDWORKS PART, and Here for

the SOLIDWORKS DRAWING.

Limit stops (seen above) were

added to keep the probe/sample from hitting the walls of this

protective cup.

Microscope mounted above sample cup. We also have the capabilites

for video capture via our 7X zoom lens. Currently trying to

upgrade the lens for greater zoom, but as you can see from the picture

the working distance has to be significantly large (~50mm).