Martensitic Magnetomechanical Measurements

Magnetomechanical Testing Equipment

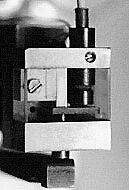

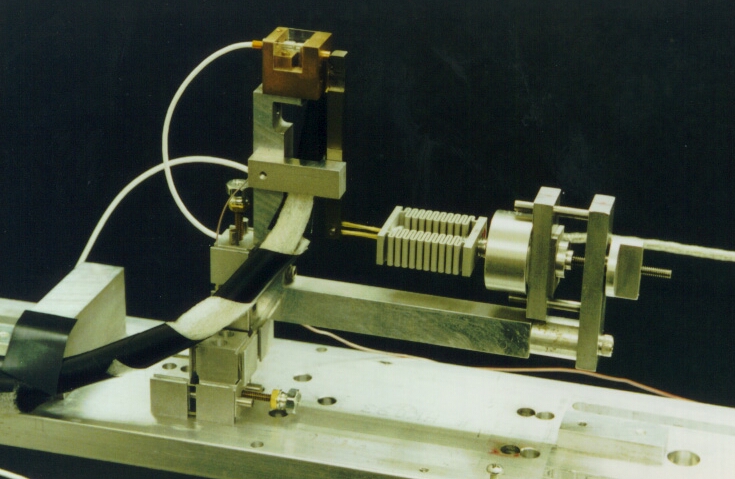

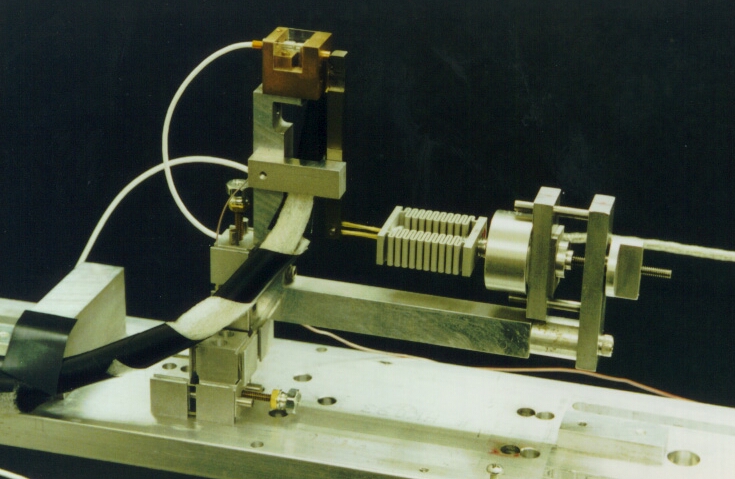

The magnetomechanical experiments were performed using the custom built compression fixture

and temperature stage setup shown below. The specimen sat inside a small temperature stage,

visible on top, which was cooled with a supply of chilled helium gas. Compression was applied

with a lever arm in series with an Al spring by adjusting the back screw, and the load was

measured with the load cell shown to the right in the picture. A series of different springs

were used depending on applied load and specimen cross section; in this way changes in the applied

load were kept to a minimum due to changes in the sample length caused by variant rearrangement.

The entire fixture was constructed from non-magnetic materials so it would not experience any

forces or torques under applied fields. The fixture was mounted to a support bar which was fixed

between the pole pieces of a Lakeshore 2T electromagnet. The electromagnet also incorporated

an optical microscope which was centered over the specimen stage, allowing video and stills

to be taken of the experiments in situ.

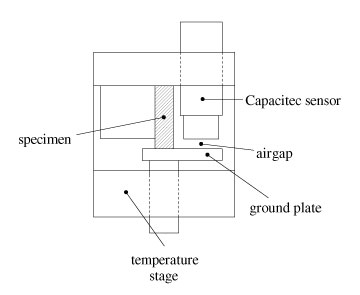

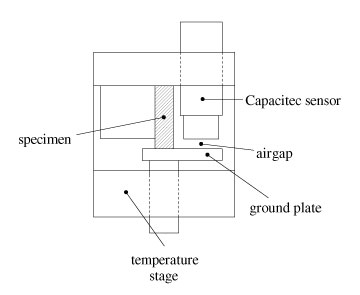

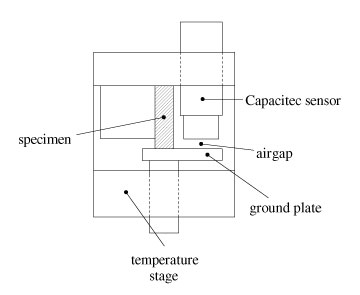

Specimen strains were measured using a Capacitec capacitive displacement sensor which was built

into the specimen stage. Loads were applied to the specimen using a lever arm which pushed

on a pin which slid in a bore in the stage. The end of the pin had a plate which applied stress

to the end face of the specimen, and also acted as a ground plate for the sensor. Changes in the airgap

between the sensor and the plate due to specimen strain were converted to a strain measurement.

Capacitive sensors have high accuracy and resolution; in this experiment the sensor was calibrated

to a resolution of 2 microinches. For the specimen geometries used, this translated to roughly

7 me .

|

Specimen

stage |

Prev Next

Magnetomechanical pages:

Go to:

My bio

Home page